Lab

Overcoming the Challenges of Zinc-Air Battery Commercialization:

The Fruits of Joint Department Cooperation

HYU-KITECH Joint Department

- Written by · YeongIm Park

- Photo by · ChoWon Son

Development of Catalyst, the Key to Zinc-Air Battery

In August, a fire broke out involving an electric vehicle in an apartment underground parking lot, once again raising concerns about the potential fire risks associated with lithium batteries. Lithium-ion batteries are the most widely used secondary batteries and yet they pose safety challenges due to their use of flammable liquid electrolytes. This has spurred significant research into alternative technologies such as all-solid-state batteries using non-flammable solid electrolytes and nextgeneration secondary batteries. Among the options, zinc-air batteries can generate electricity through the electrochemical reaction of oxygen (O₂) from the air and zinc (Zn) and thus, are gaining attention as potential replacements for lithium-ion batteries.

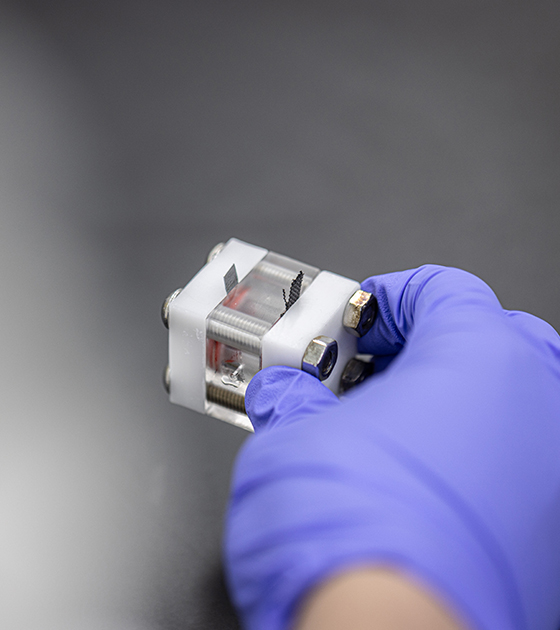

“Compared with widely used lithium-ion batteries, zinc-air batteries theoretically have about three times the energy density. They use aqueous electrolytes which reduce fire risks and are more favorable to the environment due to the lower carbon emissions during manufacturing,” explained researcher Changho Lee, who recently developed a high-durability air cathode catalyst material for zinc-air batteries. However, the need to use expensive precious metal catalysts like platinum (Pt) and iridium oxide (IrO₂) and their low durability remain significant obstacles to commercialization. To address this problem, Lee focused on developing affordable, durable catalyst materials.

His research led to the successful development of high-durability alloy nanoparticle catalysts by employing trace amounts of platinum and cobalt (Co) catalysts in ionic form to a nanofiber-type multi-component oxide support, and by controlling the ex-solution phenomenon where metal ions are selectively exposed on the surface.

“Through simulations, we discovered the mechanism of the ex-solution phenomenon and the active reaction sites of the catalyst. When applied to zinc-air batteries, our catalysts demonstrated higher charging-discharging efficiency and more than three times the lifespan of existing precious metal catalysts. This research is significant because it identifies new materials that address the high cost and low lifespan issues associated with catalysts, and makes possible future commercialization.”

The results of this research are promising in terms of the development of next-generation secondary batteries and have potential applications in various energy material fields. One such area involves fuel cells and electrolyzers, where low-cost and highdurability catalysts are needed. This achievement has been recognized and published online in the July issue of the Applied Catalysis B: Environment and Energy, a leading international journal in the environmental and energy fields.

“Developing a broader perspective

and problem-solving skills, and gaining

practical research experience at the institute

will significantly benefit students’ future

employment and career development.”

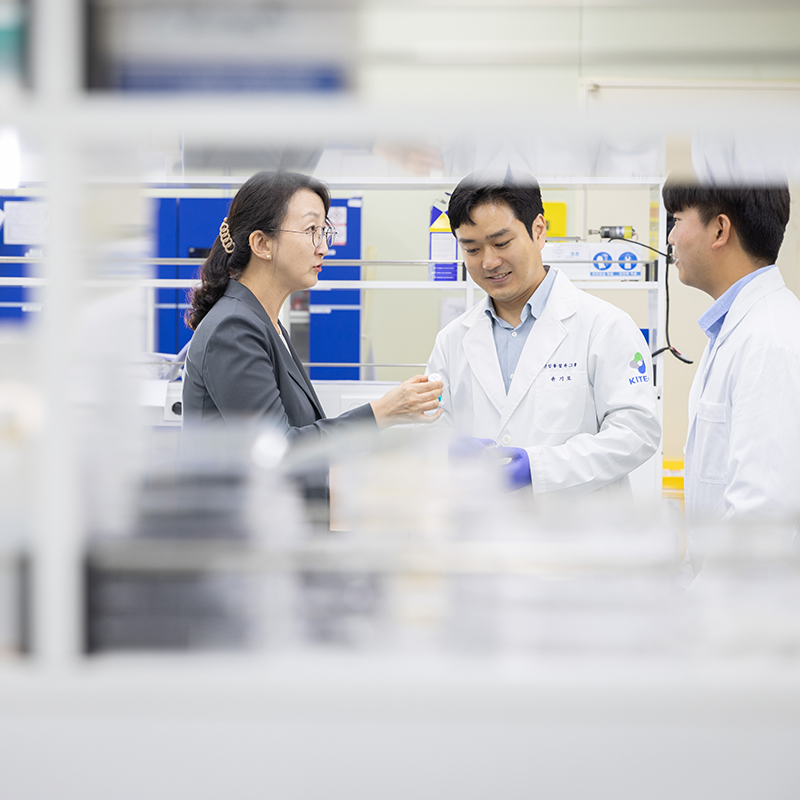

An Ideal Collaboration Between ERICA and KITECH

The research is also significant for another reason. Since 2021, Hanyang University has been operating a graduate program called the ”HYU-KITECH Joint Department” in collaboration with the Korea Institute of Industrial Technology (KITECH), located within the ERICA campus. The aim is to nurture specialized talent needed in the Fourth Industrial Revolution. The aforementioned research is a product of the Joint Department. Researcher Chang-ho Lee was an undergraduate student in Prof. Sunyoung Lee’s lab. He decided to pursue further studies in the Joint Department upon graduation, following Professor Lee’s recommendation. Since Mr. Lee has had a keen interest in the energy field, he was encouraged to study under Dr. KiRo Yoon at KITECH, where research on secondary battery and fuel cell materials was being conducted.

“This research began with the integration of the research fields of Prof. Sunyoung Lee and Dr. KiRo Yoon. As an undergraduate student, I participated in various studies on the synthesis of oxide nanofibers using electrospinning in Prof. Lee’s lab. Based on that experience, I joined the Joint Department and started research in Dr. Yoon’s research field, developing electrode catalyst materials that are crucial for next-generation batteries.”

The success of this research demonstrates the synergetic effects of the Joint Department’s collaboration between ERICA and KITECH. Students in the Joint Department spend their nonclass hours conducting research in KITECH’s laboratories and receive guidance from their professors on a weekly basis, just as other graduate students do. In other words, students in the Joint Department have mentors. According to Prof. Lee, Mr. Lee ability to employ his skills through joint supervision was a key factor in achieving outstanding results.

“The advantage of the Joint Department lies in the opportunities to utilize the research institute’s equipment and infrastructure, as well as to participate in R&D projects centered on practical applications that are often inaccessible for other graduate students. This experience helps students develop a broader perspective and problemsolving skills, while allowing them to balance their academic focus with practical research experience. Furthermore, the skills and practical research experience gained at the institute are invaluable for future employment and career development.”

Anticipated Results from Ongoing Collaborative Research

Dr. Yoon also highlighted the benefits of the Joint Department, noting the advantage of utilizing material analysis and evaluation infrastructure not available at ERICA. He further emphasized the advantages of human resource exchanges.

“Recently, the research institute has faced challenges in securing research personnel. Fortunately, the Joint Department has helped to create an environment where we can work with outstanding talent and professors. Additionally, the proximity of ERICA to the institute reduces travel time and energy, which is often consumed when working across distant institutions. I hope that this will lead to even more opportunities for collaboration with Hanyang University professors in the future.”

The next step will be to conduct joint follow-up research on this study. The research has revealed the vast potential for discovering high-efficiency catalyst combinations through the control of the multi-component ex-solution phenomenon. However, the enormous time and cost required for high-temperature heat treatment remains a challenge. Prof. Lee anticipates that substituting this heat-treatment process with flash-light sintering technology, available in the lab, could dramatically reduce material synthesis time.

“Through preliminary research with Dr. Yoon’s team, we have already confirmed that similar exsolution phenomena can be achieved using only flash-light sintering. Therefore, we aim to secure technology that enables easier production of materials with optimal performance by screening various catalyst material combinations.”

Building on the trust and collaboration established so far, there are high expectations for even greater synergy in future joint research.

Through the operation of the Joint Department, an environment has been created where outstanding talent and faculty can collaborate on research together.

Through the operation of the Joint Department, an environment has been created where outstanding talent and faculty can collaborate on research together.